Company once had largest wheel shop in world

Thomas Hill, an inventor and Quincy industrialist, was the key figure in starting the Electric Wheel Co.

This long-tenured Quincy company was absorbed by Firestone and later became part of Titan International.

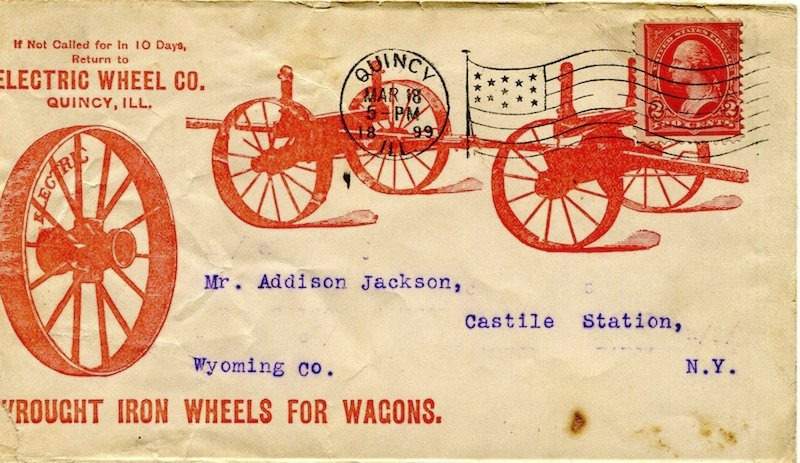

There are a number of other sources on this well-known company, including articles by others in the "Once Upon a Time" series. Consequently, this discussion concentrates on the start of the company and the initial activity of making metal wheels.

When the Quincy Metal Wheel Co. was sold in 1891, two of the principals, J.R. Little and P.B. Williams, became stockholders in the J.R. Little Metal Wheel Co. That company based its products and manufacturing on Little's patents.

Another principal, Thomas Hill, used his own patents to help start Electric Wheel. The process was to manufacture metal wheels using electricity to weld the parts. The hub had short projections in which the spokes were welded by means of the Thomson electric welder, making them one solid piece.

Hill filed a patent application in June 1888 for making a metallic wheel, and Patent No. 399.989 was issued March 19, 1889. The inner portions of the spokes were cast with the hub. Then the outer portions of the spokes were welded to the inner portion. This avoided the problem of a vast amount of room in the foundry to cast the hub and spokes as one piece.

Hill's Patent 470,666, Machine for Heading Spokes, covered the machine to provide the heating to secure the spokes to the wheel rim. Although filed Nov. 22, 1890, the patent was not issued until March 6, 1892.

Metal wheels were still in their infancy in the early 1890s. In spite of their durability, many farmers distrusted them because they had always used the wooden type. But there were distinct advantages to a metal wheel.

A wooden wheel depended upon the steel band or "tire" that held the rim on the spokes and the spokes firmly in the hub. When the wood dried and shrank, the spokes would become loose. A repair meant that the metal tire had to be removed, a section removed to shorten the tire, and the tire heated and pressed onto the wheel when hot. As the tire cooled, it shrank and tightened the wheel. A temporary fix was stopping the wagon in a stream, allowing the wooden wheels to soak up the water and swell tightly.

A metal wheel has the spokes fastened to the tire and attached to the hub by some means such as casting or forging. Not only did this keep the wheels from coming loose, but the steel wheels could be lighter in weight and smaller in diameter. Thus, the wagon bed could be lower to the ground, making loading easier. Also, steel wheels could be wider than wooden wheels, an advantage on soft fields and roads.

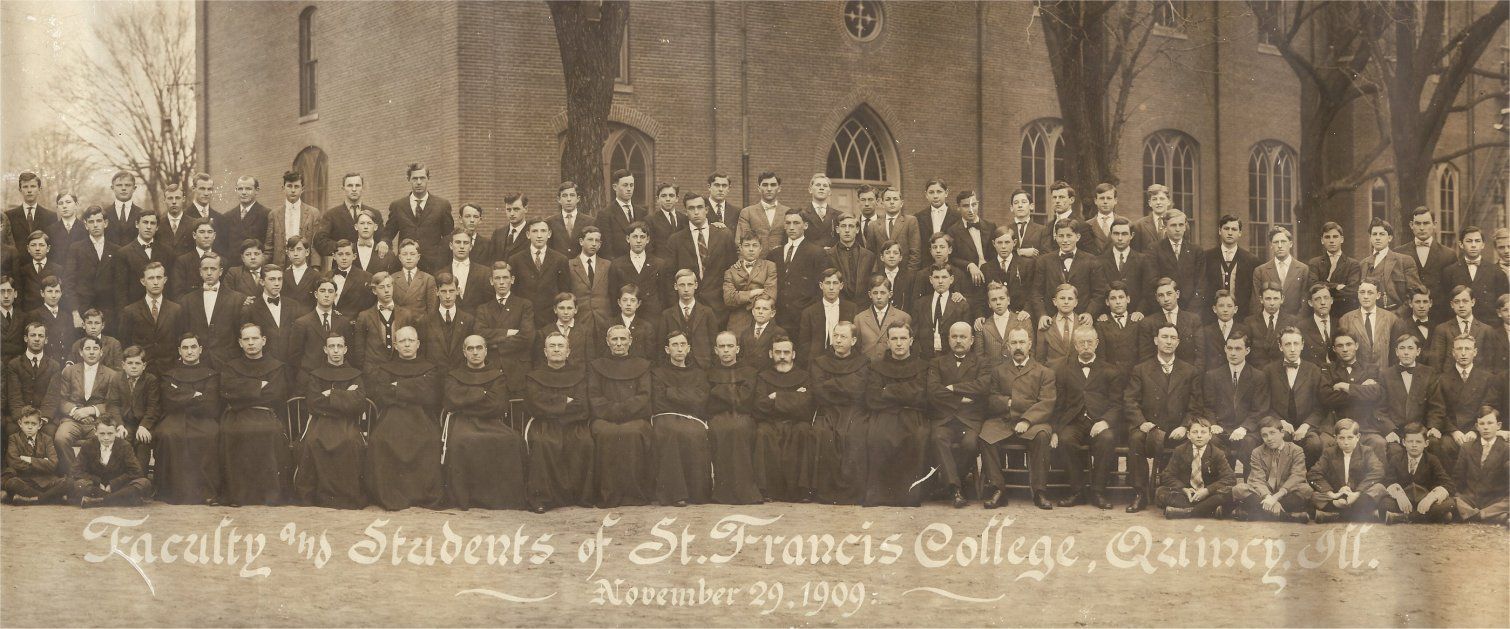

The Electric Wheel Co. was incorporated in April 1890. The incorporators were major Quincy industrialists -- Thomas Hill, S.H. Emery Jr. and Charles. G. Comstock. John Stillwell became president.

The incorporation of Electric Wheel came a year before the sale of the Quincy Metal Wheel Co. to the Bettendorf Metal Wheel Co. Hill was a stockholder in Quincy Metal Wheel, giving him simultaneous interests in two companies for making metal wheels while still retaining his position with the Smith-Hill Foundry & Machine Co.

In May 1890 the company purchased the Pfanschmidt property at Fifth and Ohio to build its plant. Although the factory was to be in full operation by Thanksgiving, the company had to obtain a 50-horsepower engine and boiler from the Smith-Hill Foundry as well as dynamos and electric welders from Boston.

There was a large amount of experimenting during that first year, and the company did not settle down to regular work until April 1891, employing six to eight men at that time. By June, it was in full operation, making a solid wheel with all welded joints. The company shipped its first full carload of metal wheels in September 1891.

Lack of adequate switching facilities in Quincy during the late 1890s had a negative effect on a number of Quincy industries. In June 1899 President John Stillwell indicated that if improvements proposed by the Wabash Railroad were not made, the company might move. By December 1901, Electric Wheel had moved to the Walton Heights district in northeast Quincy.

Electric Wheel started an early profit-sharing plan. In December 1901, the company proposed to divide its profits with employees every six months based on wages. The total sum distributed the first Christmas was about $1,000. By December 1912, Electric Wheel was giving employees with six months or more of service a bonus equal to 5 percent of their annual salary, declaring bonuses at Christmas and July 4.

Electric Wheel continued to grow. Manufacturing good metal wheels led to the production of farm wagons that used the wheels. The company moved into a number of other products, including tractors. One indicator of growth was the increase in the capital stock from $25,000 to $30,000 in September 1897, to $120,000 in October 1901, to $300,000 in January 1910, to $680,000 in April 1914.

The company grew to more than 700 employees in 1923. At that time the wheel shop was the largest in the world, with a capacity of making 1,200 to 1,500 wheels a day when operating at full force.

In 1924 the three companies of Electric Wheel, J.R. Little Metal Wheel and Bush Metal Wheel comprised the second largest center in the world for the manufacture of iron wheels for agricultural implements, wagons, tractors and farm trucks.

Jack Hilbing is a retired U.S. Air Force officer with a doctorate from Stanford University. He has worked with computers in military, industry and academia. He has collected the postal history of Quincy and Adams County for 40 years.

Sources:

"Another Big Manufactory," The Quincy Daily Whig, Nov. 7, 1891, page 3.

Cook, Robert, "Thomas Hill: Quincy elevators, Electric Wheel and the 1893 Chicago World's Fair," "Once Upon a Time Series," The Herald-Whig, Sept. 12, 2014.

"Do You Know," The Quincy Daily Herald, Dec. 13, 1924, page 1.

"Electric Wheel Capital Stock: Is Increased From $120,000 to $300,000 -- Surplus Put Into The Business," The Quincy Daily Journal, Jan. 6, 1901, page 9.

"Electric Wheel Co. Prospering," The Quincy Daily Journal, Oct. 28, 1901, page 8.

"Electric Wheel Co. Increase Stock: Rapid Enlargement of Business Compels Great Enlargement of the Capital," The Quincy Daily Herald, April 29, 1914, page 2.

"Electric Wheels: Organization of a Factory for the Construction of Metal Wheels by Electricity," The Quincy Daily Herald, April 27, 1890, page 3.

"Getting Down to Business," The Quincy Daily Herald, May 18, 1890, page 3.

"Manufacture of Wheels A Big Industry: Electric Wheel Company Receivers Order From the Fuji Islands," The Quincy Daily Journal, Jan. 28, 1923, page 29.

Moore, Sam, "Electric Wheel Co. Titans of the Steel Wheel Business," Farm Collector, June, 2003. farmcollector.com/equipment/electric-wheel-co.aspx

"New Factory Starts All Departments: New Plant of the Electric Wheel Works is in Full Operation," The Quincy Daily Whig, Dec. 3, 1901, page 5.

"Profit Sharing With Its Employees: The Electric Wheel Works Distributed a Dividend Among Its Men," The Quincy Daily Whig, Dec. 27, 1901, page 5.

"Quincy Wheels Turn in Every Part of World: Metal Wheels for Farm Machine Leading Industry Here," The Quincy Daily Journal, Jan. 27, 1924, page 16.

"Talk That Hits Home: No Switching Facilities, Fewer Factories," The Quincy Daily Whig, June 8, 1899, page 1.

"The Electric Wheel Company," The Quincy Daily Journal, June 28, 1891, page 4.

"The Electric Wheel Company," The Quincy Daily Whig, Nov. 6, 1890, page 6.

The Quincy Daily Journal, April 13, 1891, page 8.

United States Patent No. 399,989, Thomas Hill, Metallic Wheel, March 19, 1889.

United States Patent No. 470,566, Thomas Hill, Machine for Heading Spokes, March 8, 1892.

"Wheels Turning in New District: The Electric Wheel Company Has Started up One Department," The Quincy Daily Whig, Nov. 28, 1901, page 5.